Welcome to the website of MATH&TECH

MathTech - your competent partner for machine learning and for the development of software, algorithms and systems for data, signal and image processing.

MathTech gives your machines the ability to see. More than 10 years of experience in industrial image processing, a multitude of demanding projects that

we have carried out for our customers and a team of young, dynamic and highly qualified employees are the basis for our success in image processing.

MathTech gives your machines the ability to see. More than 10 years of experience in industrial image processing, a multitude of demanding projects that

we have carried out for our customers and a team of young, dynamic and highly qualified employees are the basis for our success in image processing.

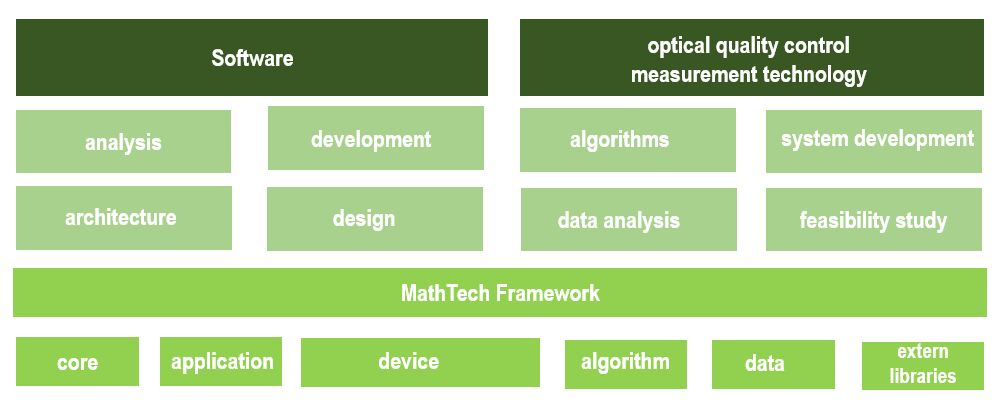

Our added value

We are strong in the development of algorithms and software solutions for industrial data, signal and image processing. With intelligent image processing

algorithms and individual software, we can solve almost any inspection task.

We are strong in the development of algorithms and software solutions for industrial data, signal and image processing. With intelligent image processing

algorithms and individual software, we can solve almost any inspection task.

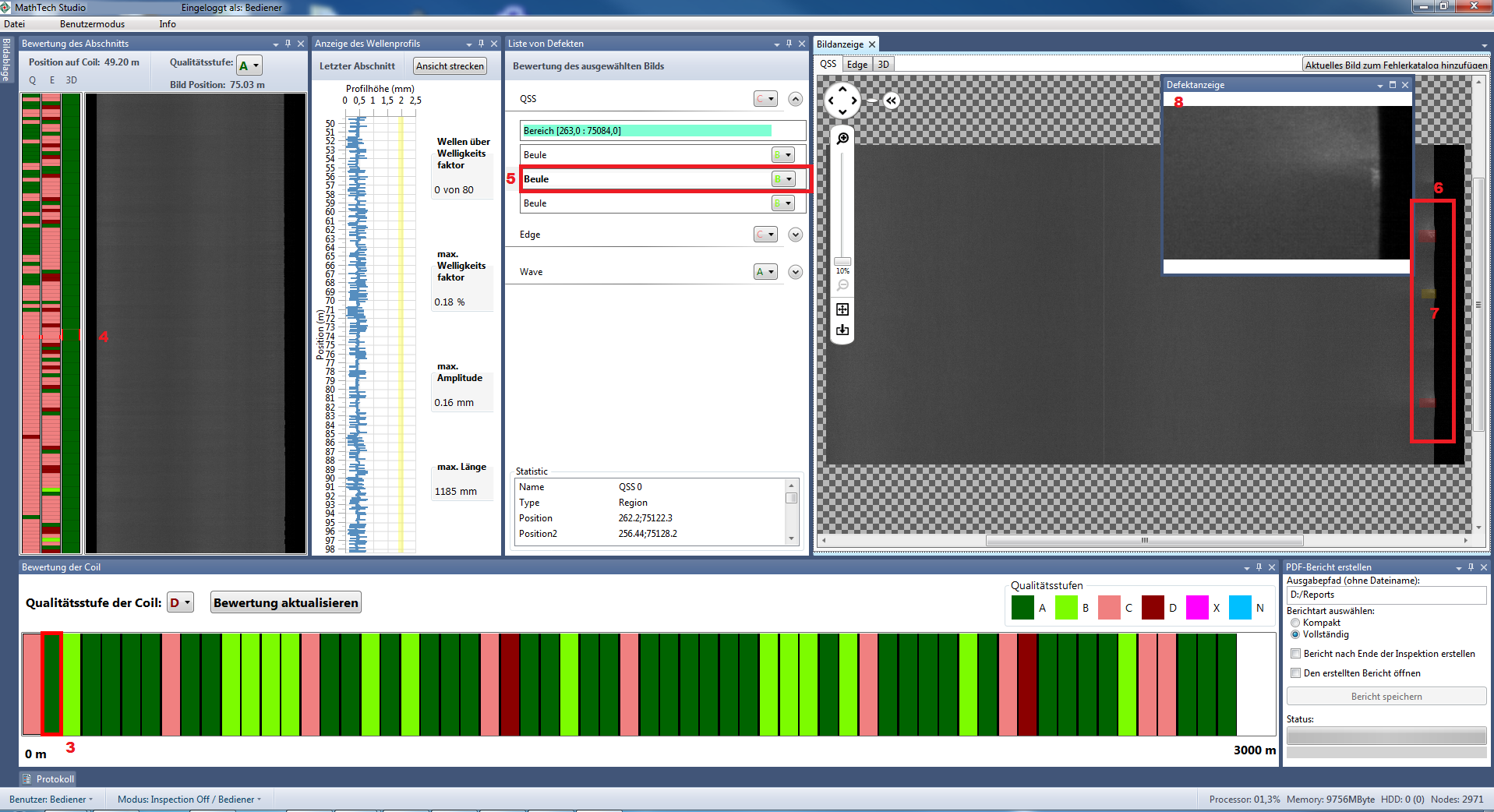

MathTechStudio

MathTechStudio is a software framework for optical quality control developed by MathTech and based on the Halcon image processing library from MVTec. This framework enables the development and construction of customized and automated inspection solutions.

The clear structure with the three modules

- The online inspection module can work as a DLL with the customer's system software or run as complete software on the customer's system. This module has access to the database to exchange data, inspection results, images and AI models.

- The offline labeling tool is used at the end customer's premises on a separate PC with access to the database. With the offline labeling tool, test results can be reloaded, evaluated and labeled. The main purpose here is to formulate and communicate the requirements from production so that the development of a new AI model can be aligned with them.

- The offline analysis tool is used to train the AI models and configure the online inspection module. In addition to training and optimization, the individual components of the AI can be validated in an offline test environment to verify the quality and check in detail how individual decisions are made. The training of the AI models can be carried out directly at the end customer's premises on a high-performance PC or at MathTech.

A clear workflow

- The images are inspected by online inspection modules using Halcon and available AI models, the results are transmitted to the system and stored in the database.

- The end customer can check the results with the offline labeling tool and marks the relevant images or areas as defects or non-defects with different classes. This information is also stored in the database.

- All information, images and labeled data from the end customer's experts or MathTech developers are loaded into the offline analysis tool and the AI models are retrained or further trained.

- The optimized models are then reinstalled on online inspection modules and used for live inspection.

The combination of all three MathTechstudio modules provides a flexible, expandable and scalable solution for multiple production sites.

Our general services for you:

Software and algorithms for industrial image processing

- Comprehensive advice on the subject of industrial image processing

- Feasibility studies and turnkey, individual software for industrial image processing

- Data Modeling, Data Management, Process Modeling and Mathematical Modeling

- Algorithm development, software development, data visualization and databases for industrial image processing

- intelligent systems and learning systems for industrial image processing

- Development with MATLAB, HALCON and Cognex

- LASKA Framework, learning system for industrial image processing machine learning

Inspection systems for industrial image processing

- 2D / 3D - position recognition

- 2D / 3D- surveying

- 2D / 3D object recognition

- positioning

- presence check

- identification by barcode, data code, OCR

- character recognition

- print inspection

- surface inspection

- color control

- robot vision

- texture inspection

- completeness check

- quality control